Biological plant with "SBR" technology for the treatment of dairy industry effluents

THE CLIENT.

- Breeding Bufalino Bianchino Gennaro, Mondragone, Caserta (IT)

- Treatment capacity: 40 m³/g

- Technology Used: SBR (Sequencing Batch Reactor)

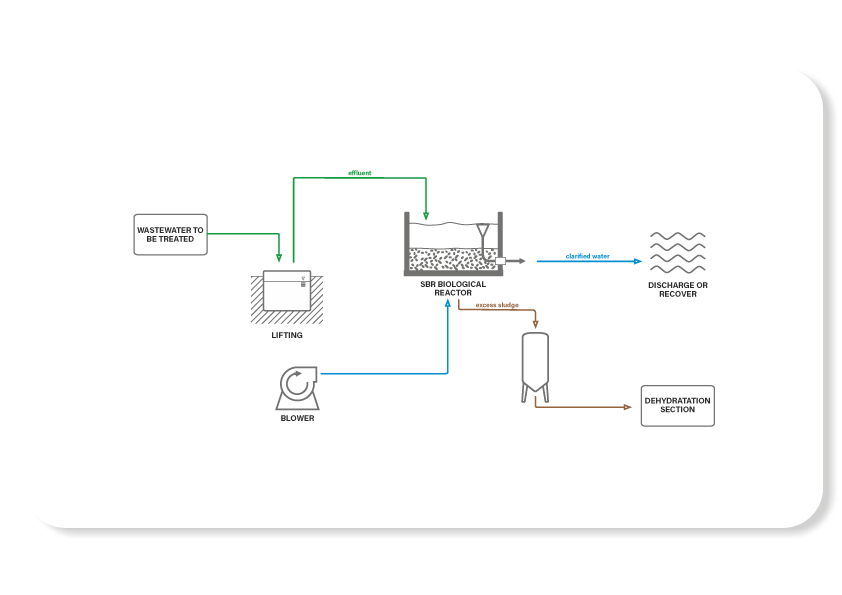

- Limits to be respected: D Lgs 152 06 Part three All 5 Tab 3 – Discharge to surface water

THE PROBLEM

The processing of buffalo milk for mozzarella production produces wastewater with a high organic load (COD, BOD5) and with concentrations of nitrogen (TKN), phosphorus (P) and fatty substances above the limits allowed for discharge to surface water or public sewer.

THE GOALS

Allevamento Bufalino Bianchino Gennaro, has built a new milk processing site, employing the highest quality standards, both in the machinery used and in the buffalo mozzarella production chain.

It is in this young, ambitious, and expanding environment that the need for the construction of a wastewater treatment plant, which meets the following requirements, arises:

- Performance guarantee even in the presence of variations such as quantity of effluent to be treated

- Need to place a sewage treatment plant in an urban setting

- Reduction of environmental impacts space, odors, noise

- Process flexibility

- Minimizing operating costs

THE PLANT.

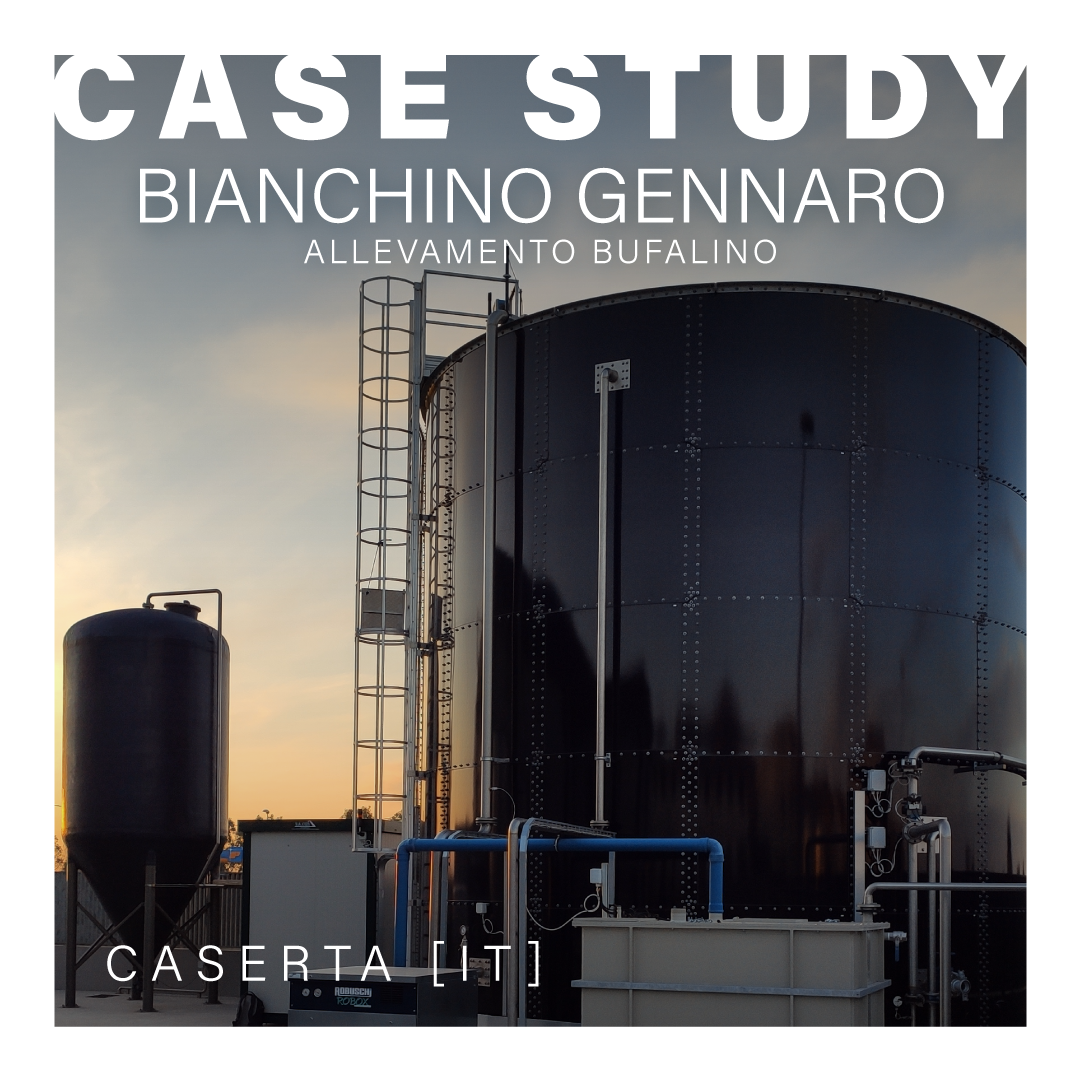

The heart of the plant is the SBR biological reactor in which the different stages of treatment

(homogenization, oxidation, denitrification and sedimentation) occur in a temporal sequence and not spatially as in traditional biological plants (CAS, MBR, MBBR).

A section is provided upstream of the reactor for removal of suspended grease. The surplus sludge is sent to a thickening tank before final disposal.

THE BENEFITS.

- No initial storage and homogenization tank is required for the effluent to be treated

- High resistance to a sudden rise in organic input load

- Absence of recirculation of both the activated sludge since there is no settling tank and the aerated mixture during the denitrification phase

- High flexibility, as it is possible to change the duration of the different treatment steps, adapting them to the actual characteristics of the effluent to be treated

- Smaller footprint than conventional biological plants

- Quick installation of the biological reactor made of vitrified steel. It is only necessary to provide a concrete slab for the placement of the reactor

- Ability to control and manage the plant remotely via PLC networking

- Low consumption of chemical reagents and electricity

RESULTS.