Plant for treatment of stormwater runoff from forecourts

The Plant treats first rain water produced by runoff from the yards of a composting plant The amount of water to be treated is 180 m³ per rain event.

THE CLIENT.

- Maia Rigenera Srl, FORSU composting plant, Lucera, Foggia (IT)

- Treatment capacity: 4 m³/h

- Technology used: Physical chemical treatment for removal of suspended and colloidal solids, complete with final filtration section on sand and activated carbon for adsorption of substances

residual organic

THE PROBLEM.

First rainwater is identified as the runoff from impermeable/permeable surfaces produced by a rain event. Depending on the activities at the site, they may have different characteristics and must therefore be appropriately treated prior to discharge into the final receptor.

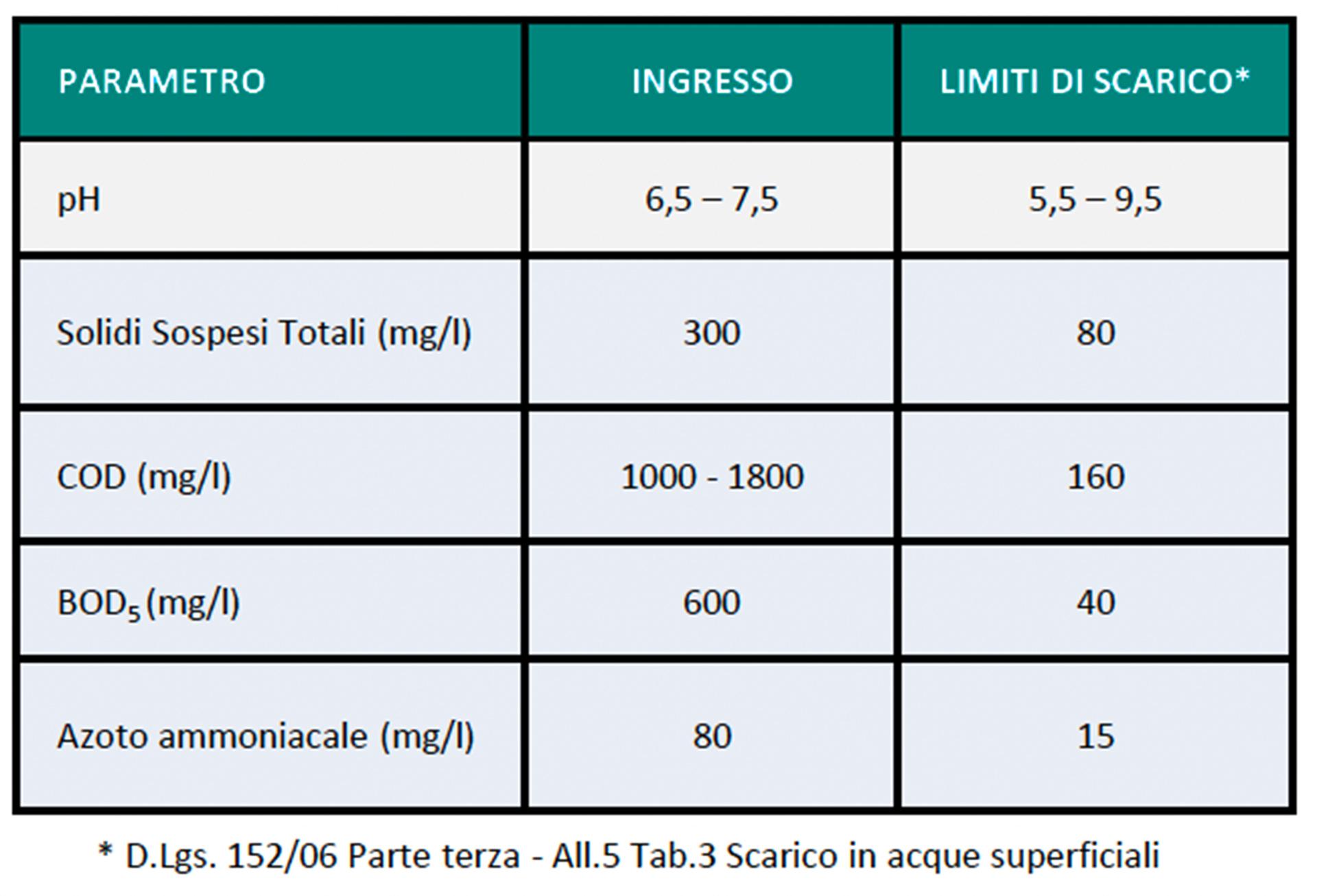

In the present case, they have high organic load (COD and BOD5) and suspended solids and ammonia nitrogen concentrations above the limits allowed for discharge to surface water The average characteristics are shown in the table opposite.

THE GOALS.

- High pollutant abatement yields. The effluent must have characteristics that comply with the limits stipulated in D. Lgs. 152/06, Tab.3 for discharge to surface water

- Flexibility of the plant with respect to changes in incoming water quality

- Easy and reliable PLC-assisted management

- Small footprint

- Ability to take advantage of the reliefs from the Industry 4.0 plan

THE PLANT.

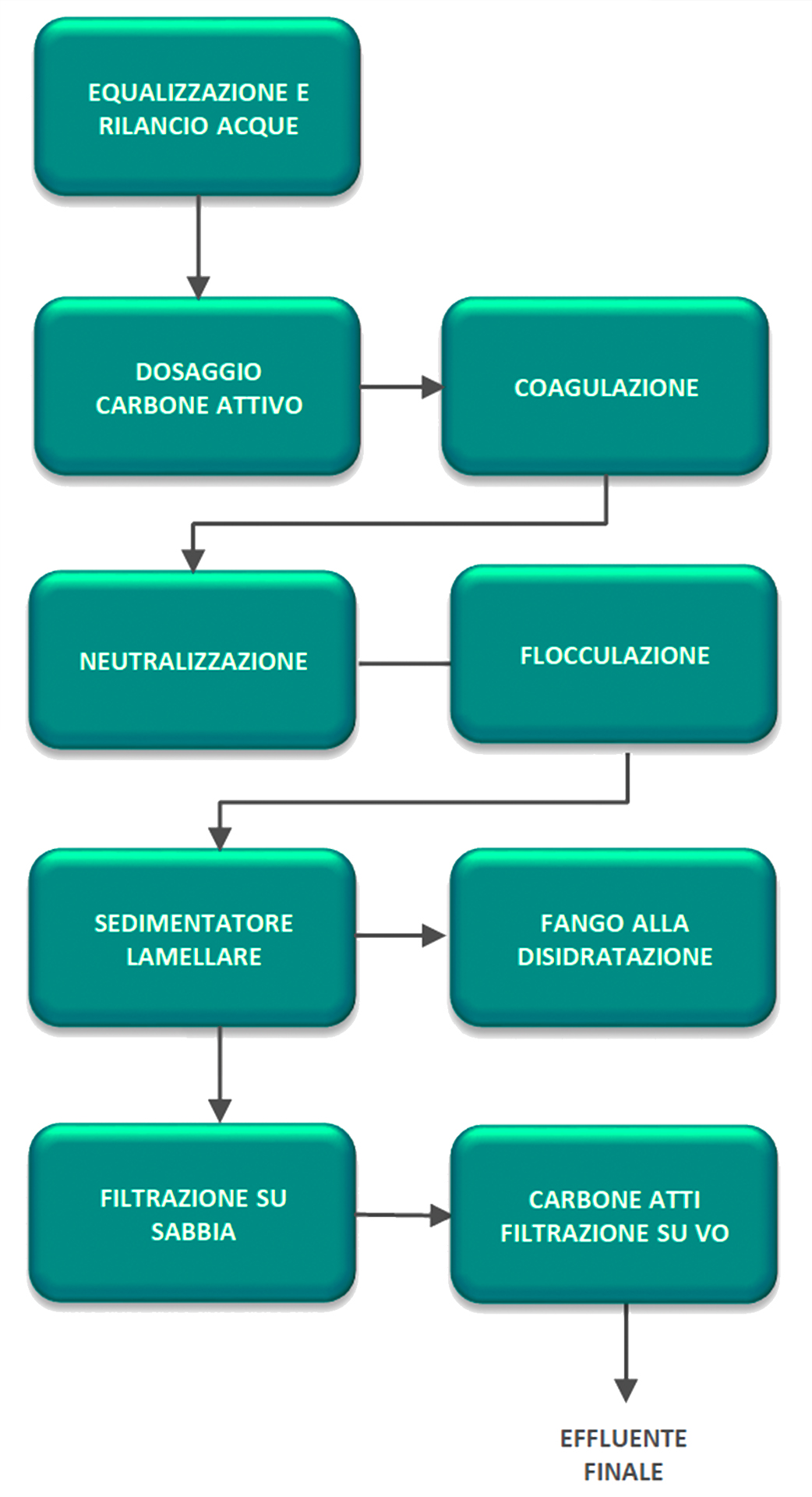

Screening, equalization and lifting: a screen is installed at the inlet of the equalization tank to remove coarse solids. From the storage tank the effluent is pumped to treatment.

Chemical-physical section:

- Adsorption with powdered activated carbon for removal of soluble organic fraction;

- Coagulation to promote destabilization of colloids and promote aggregation of suspended solids;

- pH neutralization;

- Flocculation to increase the size of the sludge flocs and improve sedimentability.

Lamellar sett ling: separation of suspended solids from the clarified is achieved. Sludge extracted from the bottom of the decanter is sent for final dewatering.

Final filtration section: the clarified output from the sedimenter is sent to a sand and activated carbon filtration for removal of suspended solids and residual organic matter, respectively. Filter backwash waters are sent to the head of the plant.

I RESULTS