MBBR facilities

In a MBBR – Moving Bed Biofilm Reactor plant, the biomass develops on a small plastic support element (carriers) submerged in the aerated mixture. The MBBR process takes place in an aerobic, anoxic or anaerobic reactor, in which the presence of the filling media on which the linked biomass allows to reach significantly higher bacterial mass concentrations than in CAS plants.

The carriers are free to move throughout the biological reactor, which is equipped with special grids that prevent them from escaping. A moving bed reactor operates continuously, it does not require backwashing, it has limited pressure drops and it is not subject to clogging.

Carriers mixing is guaranteed by the aeration system in aerobic reactors or by a mechanical mixer in anoxic or anaerobic reactors.

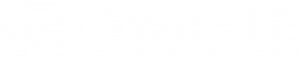

Plant diagram

MBBR is valid solution to upgrade an activated sludge plant, increasing the removal kinetics or obtaining nitrification conditions keeping constant the existing tanks’ volume. With a multi-stage configuration, it is also possible to achieve complete nitrogen removal (nitrification and denitrification), operating with multiple reactors with different load conditions.

MBBR plants require the presence of a subsequent secondary sedimentation or flotation unit to separate the sludge from the final clarified.

MBBR plants, individually or in combination with other technologies, can be used to treat wastewaters deriving from the following sectors: