SBR facilities

SBR – Sequencing Batch Reactors Plants are today one of the most promising and feasible alternative techniques to the traditional biological processes for the organic carbon and nutrients (nitrogen and phosphorus) removal.

All the treatment phases (homogenization, oxidation and sedimentation) take place in a single tank in a temporal sequence, contrary to what happens in continuous plants (CAS) where the phases take place in spatial sequences, in physically separated tanks. This solution allows to reduce the overall dimensions of the system and the electricity consumption, and to improve the kinetics of organic load removal.

The SBR process involves a variable volume reactor. The total VT reactor’s volume consists of two independent and controllable fractions, defined as the stationary volume V0 in which the sedimented sludge is present and the volume VF which represents the volume of effluent fed and discharged each treatment cycle. The reactor reaches its maximum level at the end of the feeding period.

The duration of the cycle and its configuration can be changed in order to find the most convenient equilibrium of variables.

SBR biological treatment plants turn out to be a flexible and easy to manage solution, since it is possible to work on all the above-mentioned variables, and all the processing steps are carried out in a single reactor.

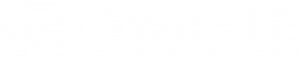

Plant diagram

Avoidance accumulation and homogenization tanks;

Variability of flow rates and polluting loads accepted;

Avoidance of recirculation;

Space optimization (smaller dimensions);

Quick installation and avoidance of civil works;

Low consumption of reagents and electricity.

SBR plants, individually or in combination with other technologies, can be used to treat wastewaters deriving from the following sectors: