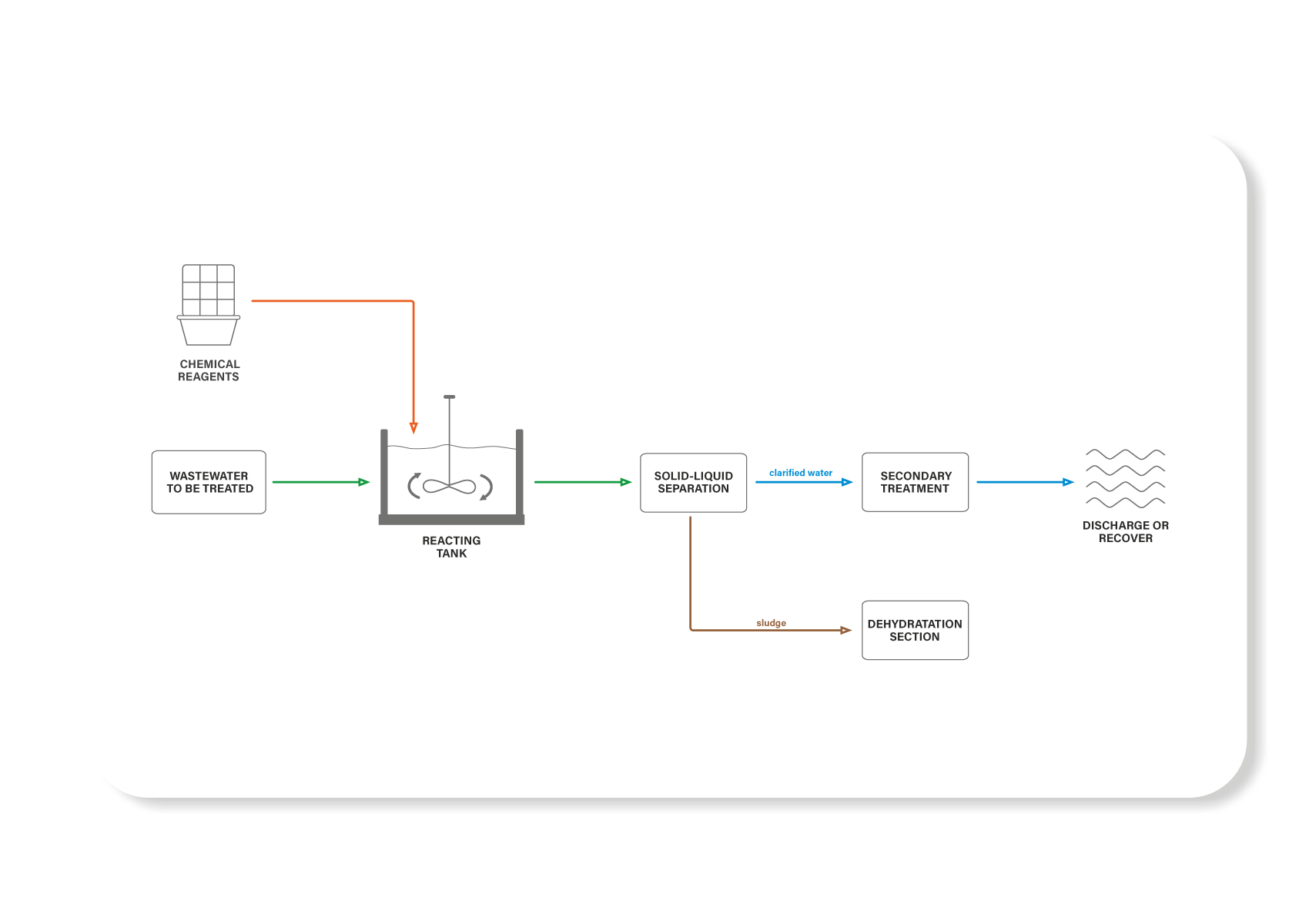

Chemical-physical plants

Continuous or discontinuous (batch) chemical-physical treatment plants are used for the wastewater treatment in which both organic and inorganic pollutants may be present.

The first phase consists in specific chemical products dosing which, depending on the pH value of the environment in which they react, cause the oxidation or pollutants reduction, first making them insoluble and then removing them with the subsequent neutralization phases, coagulation flocculation for which other specific products are used (such as acids, bases, coagulants and polyelectrolytes).

The second phase treatment consists in the sludge separation from the clarified water by sedimentation or flotation. The sludge is then sent to the final treatment section to increase the concentration of dry matter by treatment with a filter press, centrifuge or rotary vacuum filters

The clarified is sent instead:

- o sand filtration to the removal of suspended solids;

- Activated carbon filtration to the absorption of residual traces of pollutants (COD, surfactants, free chlorine);

- Filtration on selective resins to specific pollutants removal (boron, nitrates, traces of heavy metals).

Among the chemical-physical processes, of particular interest are the advanced oxidation treatments (AOP); among these the best known is the FENTON process, based on the reagent’s use consisting of hydrogen peroxide and salts of divalent iron in an acidic environment. The process finds application in the treatment of industrial waste with a high concentration of COD, surfactants, toxic compounds such as benzene, toluene, PCB, etc.

One of the most interesting fields of application of the process is the pre-treatment of industrial waste before a biological refining process, to remove the toxic/inhibiting soluble organic substances or to transform them into simpler and therefore more easily biodegradable molecules.

The chemical-physical treatment plants are also designed and built according to the available areas. The remote control system allows to continuously monitor the operation of the plant and to make updates or changes to the software directly from the Biowaste’s headquarters, thus reducing time and, above all, the costs of intervention

Plant diagram

The chemical-physical treatment plants, individually or in combination with other technologies, can be used to treat wastewaters deriving from the following sectors: