Evaporation Plants

Evaporation is the process able, through a boiling solution, to remove part of the solvent present in it and to concentrate the solution itself. It can be applied to treat industrial wastewaters, even with a very complex matrix, in which both organic and inorganic pollutants may be present.

It is used when cheaper alternative treatment techiques do not allow satisfactory results to be achieved, in order to obtain an effluent suitable for discharge or internal recycling.

Against investment and management costs that make it one of the most expensive waste water treatment systems, unless thermal recovery energy is available, it guarantees very high yields, because it allows to obtain the maximum percentage of purified water and the minimum amount of final concentrate (respectively up to 90-95% of distillate and 5-10% of concentrate).

Different types of evaporators and different process variants have been developed to take into account the different nature of the solutions to be treated, the required evaporation yield, the type and cost of the available energy sources.

The types of vacuum evaporators that Biowaste can offer are:

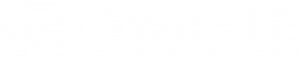

- SINGLE OR MULTIPLE EFFECT HOT WATER OR STEAM EVAPORATOR

This type of plant is used when low-cost thermal energy is available and obtained:- By burning the biogas generated in landfills;

- Using the hot water produced by the engines cooling and / or the exhaust fumes of the cogenerators;

- By recovering the heat present in the other cooling waters used within the company.

- MECHANICAL VAPOR RECOMPRESSION EVAPORATOR (MVR)

- HEAT PUMP EVAPORATOR

For these two types of systems, there is no need for thermal energy, as operation is by absorption of electricity only. In particular, for the mechanical recompression of steam the consumption is between 40 – 50 kW / t of evaporated water while it rises up to 150 – 200 kW / t for heat pump plants.

One of the factors that most affects the investment cost of evaporation plants is the construction material of the parts which are in contact with the solution to be treated. Depending on its composition, pH and the plant’s operating temperature, it’s possible to use:

- AISI 316 L (1.4435)

- AISI 316 Ti (1.4571)

- Duplex 904 L (1.4539)

- SAF 2507 (1.4410)

- Graphite or PVDF

Depending on the characteristics of the solution to be treated, the type of heat exchangers that could be used are:

- Plates heat exchanger;

- Horizontal or vertical tube bundle;

- With a scraped surface.

Plant diagram

Evaporation plants, individually or in combination with other technologies, can be used to treat wastewaters deriving from the following sectors: