Slaughterhouse Waste Plant

Biowaste designs and builds biomethane and biogas plants fueled by by-products from meat processing.

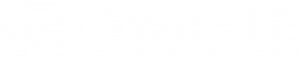

Plant diagram

Advantages of Biogas produced from Slaughterhouse waste

Eventual nitrogen's removal contained in the digestate;

Digestate improvement and stabilization;

Savings on wastewater disposal;

Treatment of odor's emissions.

Pretreatment, Anaerobic Digestion and Storage.

Intestinal parcels

The pig intestinal packs will undergo a first shredding treatment and then they will be sent to the thermal treatment as required by law;

Blood

The blood will be delivered, by pumping, to the planned THERMAL treatment;

Heat treatment

The heat treatment phase, sized for an operation of 6h/day x 5 days/week. Provides for pasteurization of slaughter waste under certain conditions of pressure and temperature with a residence time to neutralize pathogens in compliance with current regulations;

Storage

The mixture of blood and intestinal packs resulting from the pasteurization process will be stored inside a steel tank, complete with absolute filters for the elimination of possible odor emissions, and then continuously fed to the loading tank;

Slaughter float

The slaughterhouse, resulting from the processing operations and the washing phases, is physically separated before sending the discharges to the purification plant;

Liquid Fats

The liquid fats will be directly sent, with continuity, to the pretank through a special supply line;

Odor emission treatment

The room dedicated to hosting the pre-treatment phases will be equipped with an odor treatment line, created through the installation of an adequate suction system and the use of service water in order to obtain the abatement of odor emissions;

Primary and secondary digesters

Biogas treatment

Consisting of biological desulphurization with oxygen quality control inside the biogas and washing towers;

Upgrading System

For the purification of biogas with methane concentrations above 97.5% vol;

Cogenerator

Fueled by biogas for the electrical and thermal energy production;

Liquid effluent treatment plant

Chemical-physical or biological plants in order to obtain a wastewater with characteristics suitable to be discharge into the sewer system or into a surface water body (Italian Legislative Decree 152/06).

Solid/liquid separation

Of the digestate by centrifugation or screw separators;